New architecture could power super-efficient hypersonic vehicles, revolutionizing high-speed flight

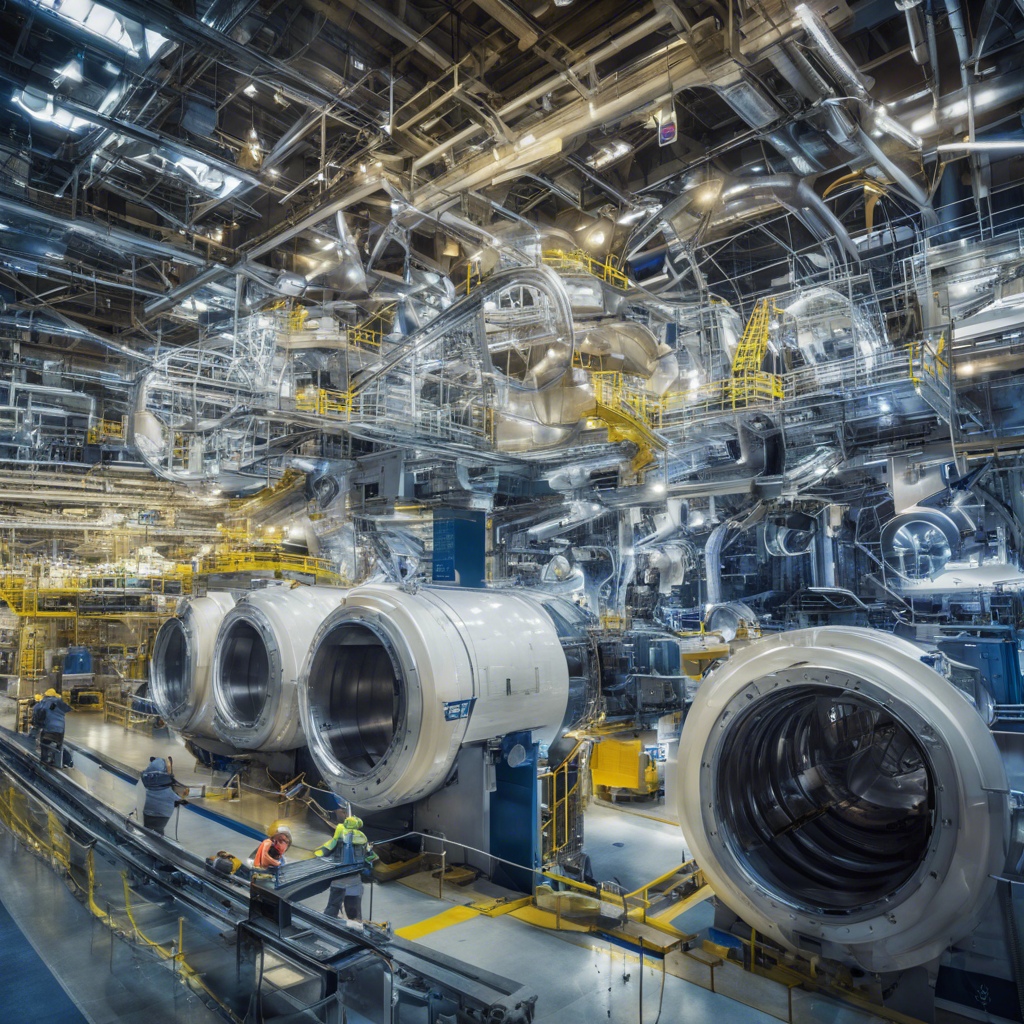

GE Aerospace has revealed its comprehensive hypersonics program, showcasing a world-first hypersonic dual-mode ramjet (DMRJ) rig test with rotating detonation combustion (RDC) at its Research Center in Niskayuna. This breakthrough could pave the way for high-speed, long-range flight with increased efficiency. The milestone, along with GE Aerospace’s extensive portfolio of programs, positions the company as a leader in the hypersonic sector as it prepares to launch as a standalone entity in the second quarter of 2024.

Rotating Detonation Combustion (RDC) Revolutionizes Hypersonic Propulsion:

GE Aerospace’s successful demonstration of a DMRJ with RDC marks a significant advancement in hypersonic propulsion. Unlike typical air-breathing DMRJ propulsion systems that require supersonic speeds to operate efficiently, GE Aerospace’s rotating detonation-enabled dual-mode ramjet can function at lower Mach numbers, resulting in improved efficiency and extended range.

Innoveering Acquisition Boosts Expertise:

GE Aerospace’s acquisition of Innoveering has played a crucial role in augmenting its dual-mode ramjet engine capabilities. With Innoveering’s expertise in hypersonic propulsion and ramjets, combined with GE Aerospace Research’s decade-long work in rotating detonation combustion and extensive experience in high Mach research and engine development programs, the company is well-positioned to deliver cutting-edge hypersonic propulsion systems.

High-Temperature Materials and Electronics:

GE Aerospace’s hypersonics program also focuses on the development of high-temperature materials and electronics. The company is a pioneer in using ceramic matrix composites (CMCs) in high-pressure turbines for commercial aircraft, enhancing temperature capabilities and durability. Additionally, GE Aerospace researchers have demonstrated Silicon Carbide (SiC) MOSFETs that can operate at temperatures exceeding 800 degrees Celsius. These advancements in SiC technology enable the control and monitoring of hypersonic vehicles in extreme high-temperature environments.

Scaling Up for the Future:

GE Aerospace’s rapid progress in the hypersonics field is evident in the DMRJ with RDC demonstration, which took just 12 months from start to finish. The company remains on track to showcase a full-scale DMRJ with RDC next year. The team’s speed and expertise demonstrate GE Aerospace’s commitment to meeting the needs of its customers and driving advancements in hypersonic technologies.

Conclusion:

GE Aerospace’s hypersonics program, highlighted by the successful demonstration of a dual-mode ramjet with rotating detonation combustion, represents a significant leap forward in high-speed flight. With its comprehensive portfolio of programs, expertise in high-temperature materials and electronics, and strategic acquisitions, GE Aerospace is poised to lead the way in developing revolutionary hypersonic propulsion systems. As the company prepares to launch as a standalone entity, its advancements in hypersonics will shape the future of flight and pave the way for super-efficient hypersonic vehicles with unprecedented range and speed.