Olivier Andries, the CEO of French jet engine maker Safran, cautions against setting unrealistic industrial targets as global supply chains continue to grapple with the aftermath of the pandemic and other external shocks.

The head of Safran, Olivier Andries, has expressed concerns about the ability of global supply chains to meet the rising demand for aviation as travel resumes. Speaking during a visit to Morocco to sign a government pact on boosting supply chains, Andries highlighted the lingering impact of the pandemic, along with other external shocks, as major challenges that the supply chain is still struggling to overcome. Amidst this backdrop, he emphasized the importance of setting realistic industrial targets to ensure a sustainable recovery for the aviation industry.

Supply Chain Challenges and Recovery:

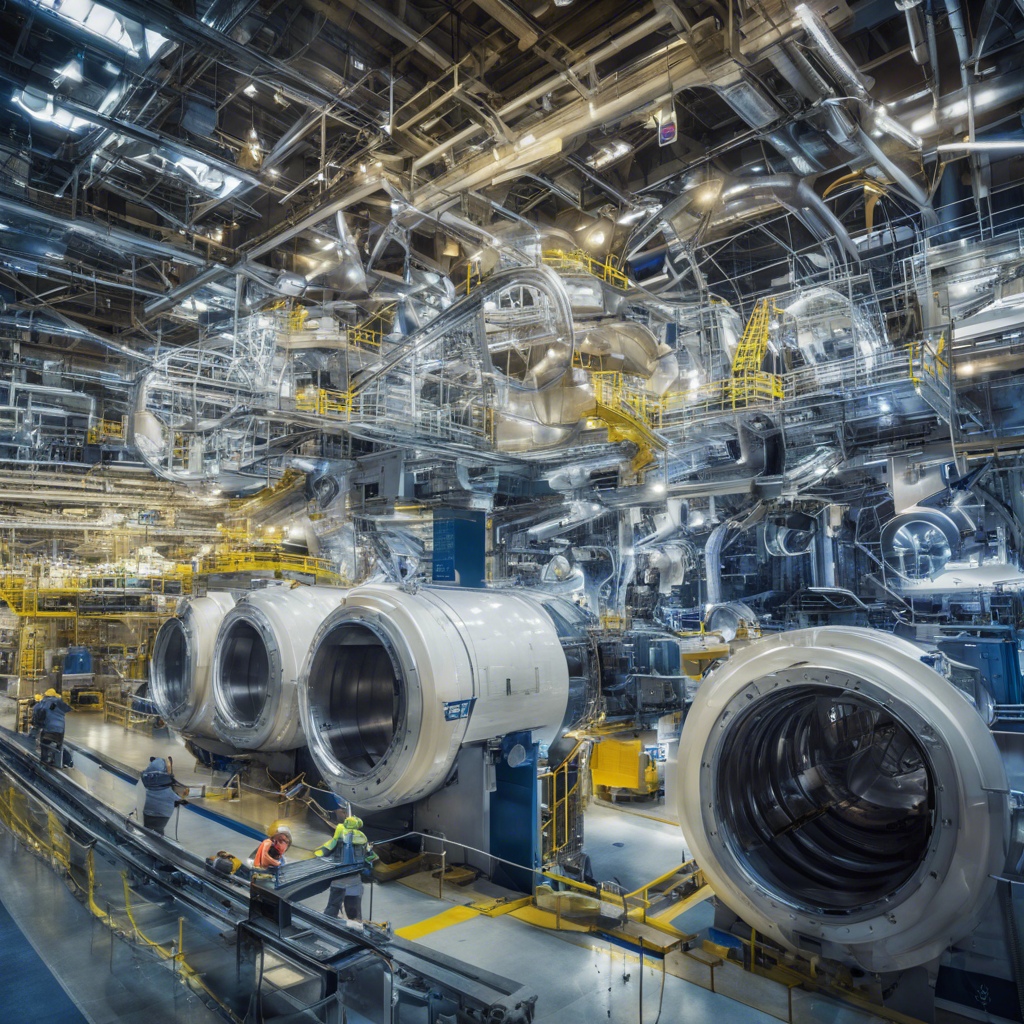

Andries pointed out that the supply chain has not yet returned to a normal level following the shocks of the pandemic, as well as other factors such as the Ukraine crisis, energy issues, inflation, and labor challenges. While demand for aviation is present, the question remains about the appropriate speed for ramping up production. Safran, in partnership with GE, produces LEAP jet engines for Boeing and Airbus, and recently had to trim its growth forecast for LEAP deliveries in 2023 due to supply issues. Andries emphasized the need to strike a balance between ambition and realism, acknowledging the pressure on the supply chain, particularly with regards to raw materials.

Setting Ambitious yet Achievable Targets:

Despite the challenges, Safran has set a preliminary target of 2,000 LEAP engine deliveries in 2024, pending final discussions with GE. However, Andries cautioned that this target already represents a ceiling due to the current state of the supply chain. He emphasized the importance of remaining realistic and not making commitments that cannot be achieved. Looking ahead to 2025, Andries stated that CFM, the joint venture between Safran and GE, would increase LEAP deliveries but that precise volumes would be determined around the middle of next year. The focus is on accommodating a return to pre-pandemic output levels, but Andries noted that planemakers have been adjusting their demand forecasts as time progresses.

Engine Supplies as a Key Risk:

Engine supplies have emerged as one of the major risks for aircraft manufacturers as they navigate the post-pandemic recovery. While Airbus has been more optimistic about raising output to meet demand, engine makers have been more cautious. Andries reiterated CFM’s readiness to meet the pre-pandemic output levels, but highlighted the tendency of planemakers to lower their demand forecasts over time. Airbus, for instance, recently pushed back its target of producing 75 narrow-body jets per month from 2025 to 2026.

Future Outlook and Local Supply Chain Development:

Andries did not provide a specific numerical estimate for 2025, but his production and market share estimates suggest deliveries of approximately 2,200-2,300 engines, accounting for spares output and deliveries for the new Chinese Comac C919 jet. As Safran seeks to address supply chain challenges, the company has signed a new framework agreement with the Moroccan government to develop local supply chains, with a particular focus on training. Safran already has a strong presence in Morocco, with engine repairs, engine nacelle production, and a joint-venture with Boeing for cabling operations.

Conclusion:

The recovery of global supply chains in the aviation industry continues to face significant challenges as it grapples with the aftermath of the pandemic and other external shocks. Safran’s CEO, Olivier Andries, has emphasized the need for a realistic approach to setting industrial targets, given the ongoing struggles in the supply chain. While the demand for aviation is evident, the speed of ramping up production must be carefully considered to ensure a sustainable recovery. As the industry navigates uncertain times, collaboration between stakeholders and the development of local supply chains will play a crucial role in building resilience and meeting future demands.