In an interview with CNBC, GE Aerospace CEO Larry Culp discusses the current state of the aerospace industry and the opportunities it presents.

The aerospace industry has faced significant challenges in recent years, with the COVID-19 pandemic causing a sharp decline in air travel and a subsequent decrease in demand for new aircraft. However, according to GE Aerospace CEO Larry Culp, the industry is now experiencing a resurgence. In an interview with CNBC’s “Last Call,” Culp shares his insights on the current state of the aerospace industry, highlighting the increased activity in both new aircraft production and the commercial aerospace aftermarket.

1: A Strong Rebound in New Aircraft Production

Despite the setbacks caused by the pandemic, Culp expresses optimism about the future of the aerospace industry. He notes that new aircraft production is experiencing a strong rebound, with airlines and leasing companies placing orders for new planes. This surge in demand is driven by several factors, including the need to replace aging fleets and the anticipation of a post-pandemic travel boom.

Culp emphasizes the importance of sustainability in this new wave of aircraft production. He highlights the industry’s commitment to reducing carbon emissions and developing more fuel-efficient planes. GE Aerospace, as a leading provider of jet engines, is at the forefront of these efforts, investing in research and development to create more environmentally friendly propulsion systems.

2: The Thriving Commercial Aerospace Aftermarket

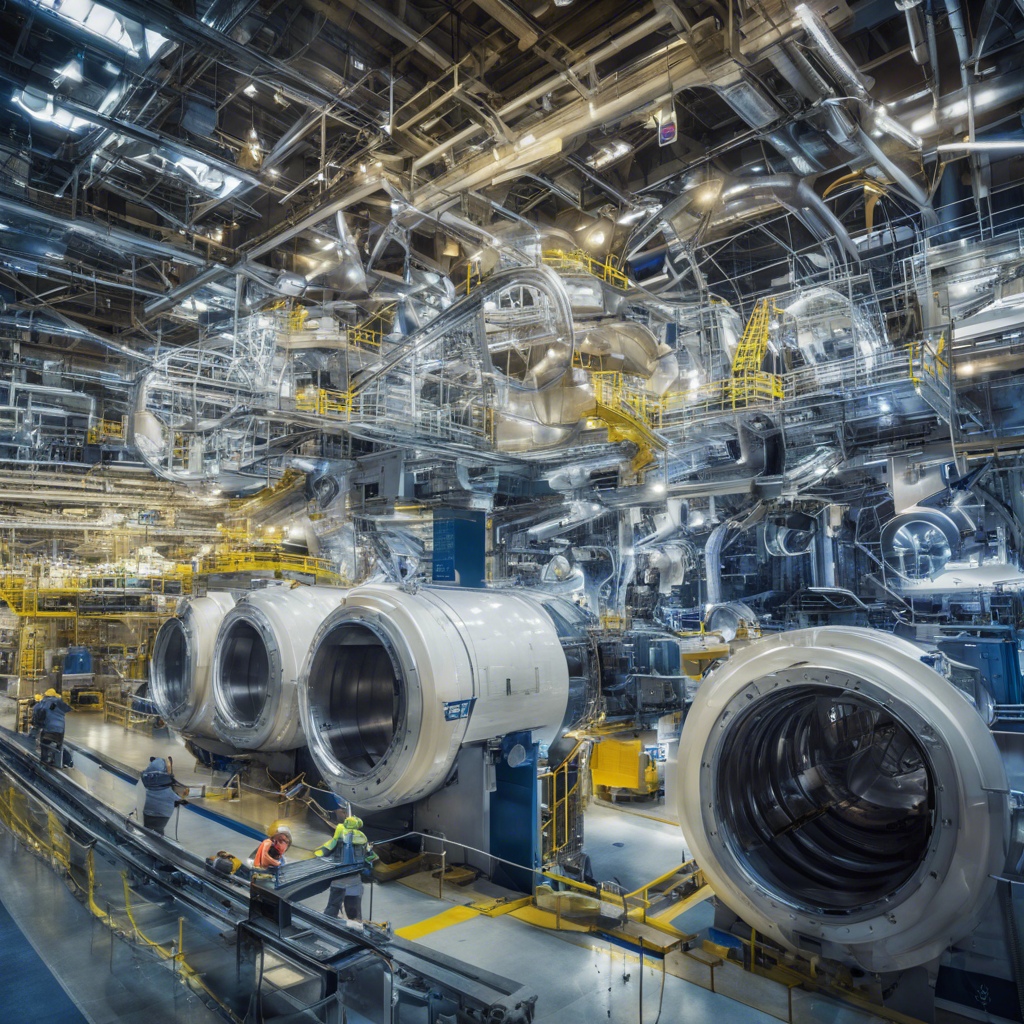

In addition to the increase in new aircraft production, Culp highlights the thriving commercial aerospace aftermarket. As airlines resume operations and aircraft return to service, there is a growing demand for maintenance, repair, and overhaul (MRO) services. This presents a significant opportunity for companies like GE Aerospace, which specializes in providing MRO solutions.

Culp notes that the commercial aerospace aftermarket “couldn’t be busier.” With airlines looking to optimize their operations and ensure the reliability of their fleets, there is a heightened focus on MRO services. GE Aerospace, leveraging its expertise and technological advancements, is well-positioned to meet this demand.

3: The Role of Technology and Innovation

Technology and innovation play a crucial role in shaping the future of the aerospace industry. Culp highlights the importance of digitalization and data analytics in improving aircraft performance and reducing maintenance costs. By harnessing the power of data, companies can identify potential issues before they become critical, enabling proactive maintenance and minimizing downtime.

Furthermore, Culp discusses the role of additive manufacturing, commonly known as 3D printing, in the aerospace industry. This technology allows for the production of complex parts with reduced weight, improved performance, and shorter lead times. GE Aerospace has been actively exploring and implementing additive manufacturing techniques to enhance its manufacturing processes and deliver more efficient and cost-effective solutions.

Conclusion:

The aerospace industry is experiencing a resurgence, with new aircraft production and the commercial aerospace aftermarket witnessing increased activity. GE Aerospace CEO Larry Culp’s insights shed light on the positive trajectory of the industry, driven by the need for fleet renewal and the focus on sustainability. With a strong emphasis on technology and innovation, GE Aerospace is well-positioned to capitalize on these opportunities and contribute to the future of the aerospace industry. As air travel continues to rebound, the industry’s recovery is set to soar to new heights.