MIT Researchers Develop Method to Overcome Challenges of Integrating Ultrathin 2D Materials

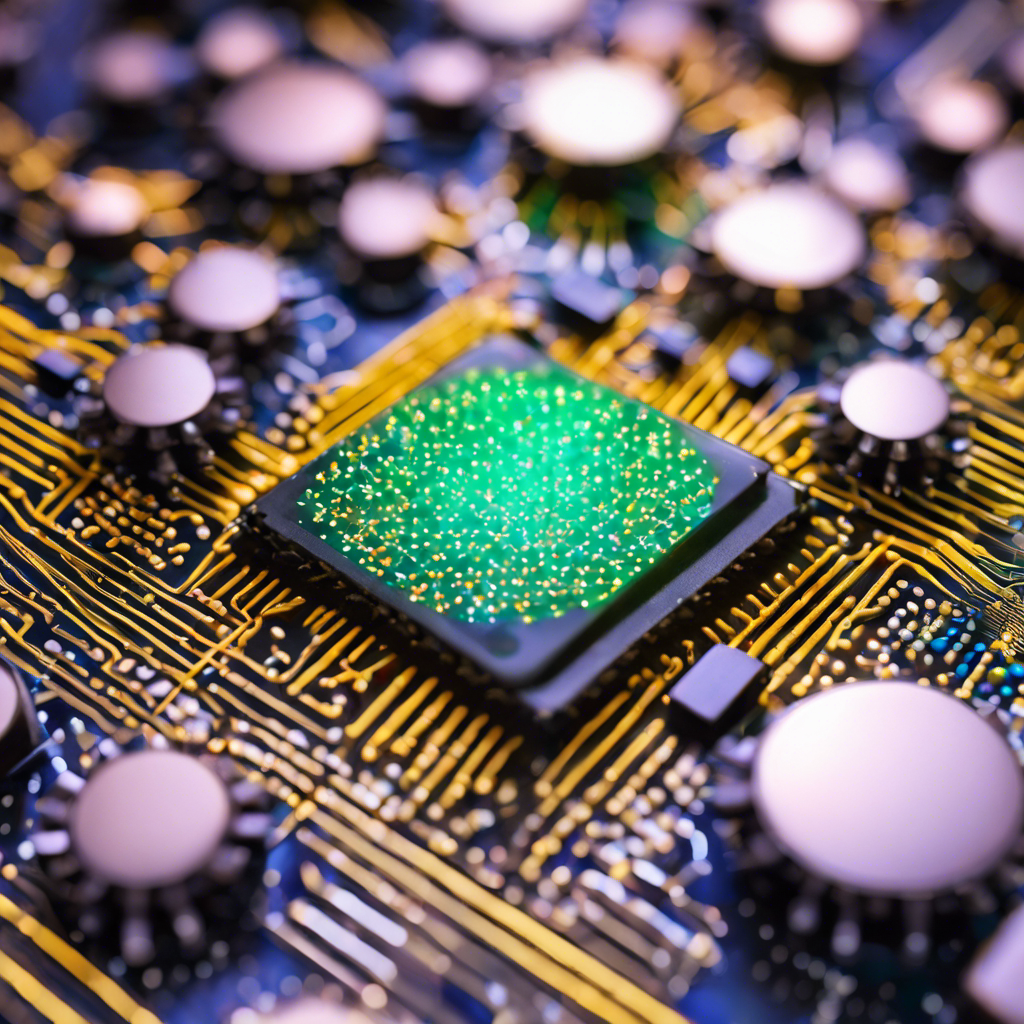

Two-dimensional (2D) materials have the potential to revolutionize the field of electronics with their unique properties. However, integrating these ultrathin materials into devices has proven to be a major challenge due to their susceptibility to damage during conventional fabrication techniques. In a breakthrough development, researchers from MIT have devised a novel method to seamlessly integrate 2D materials into electronic devices, harnessing the power of van der Waals forces and creating clean interfaces. This breakthrough could pave the way for the development of next-generation electronic devices with enhanced performance and functionality.

The Challenge of Integrating 2D Materials

Integrating 2D materials into electronic devices is a complex task due to the delicate nature of these ultrathin structures. Traditional fabrication techniques often involve the use of chemicals, high temperatures, or destructive processes like etching, which can damage the 2D materials. This limits their ability to fully leverage their unique optical and electrical properties. Researchers have been searching for a method that allows for the seamless integration of 2D materials without compromising their integrity.

Leveraging Van der Waals Forces

The MIT researchers have developed a technique that capitalizes on the natural forces of attraction known as van der Waals forces. These forces exist between all matter and can be harnessed to physically stack a layer of 2D material onto a device, creating a clean interface. However, not all materials exhibit strong enough van der Waals forces to hold them together. The researchers have overcome this limitation by embedding a low-adhesion insulator in a high-adhesion matrix, creating an adhesive surface that allows the 2D material to stick to the insulator.

A Single-Step Integration Process

The researchers’ method involves forming a hybrid surface of metals and insulators on a carrier substrate. This surface is then flipped over to reveal a smooth top surface that serves as the foundation for the desired device. The 2D material is prepared separately in a clean environment and brought into direct contact with the prepared device stack. The adhesive matrix allows for a van der Waals integration that would typically be impossible, enabling the formation of fully functioning devices in a single step. This process ensures that the 2D material interface remains clean and free from defects or contamination.

Unlocking New Functionalities

The clean interfaces created by the researchers’ method enable the 2D material to reach its full potential without being hindered by defects. This opens up opportunities to engineer the surface of the 2D material and create features or connections to other components. The researchers have successfully fabricated arrays of 2D transistors using their technique, achieving new functionalities compared to devices produced using conventional fabrication techniques. They have also demonstrated the integration of graphene onto a device, expanding the versatility of their platform.

Scaling Up and Future Applications

The adhesive matrix technique developed by the MIT researchers can be implemented at scale to create larger arrays of devices. It is also compatible with a wide range of materials and can be adapted to leverage other forces, further enhancing its versatility. The researchers envision using this platform to integrate a diverse library of 2D materials and study their intrinsic properties without the influence of processing damage. This could lead to the development of new device platforms that harness the superior functionalities of 2D materials.

Conclusion:

The integration of 2D materials into electronic devices has long been a challenge due to their delicate nature and susceptibility to damage. The MIT researchers have overcome this obstacle with their innovative method, which utilizes van der Waals forces and adhesive matrices to create clean interfaces. This breakthrough not only allows for the seamless integration of 2D materials but also unlocks new functionalities and performance improvements in electronic devices. As researchers continue to refine and expand upon this technique, the possibilities for the future of electronics are boundless.